When it comes to distilling or concentrating liquids, an innovative and powerful piece of equipment known as an Agitated Thin Film Evaporator has proven its worth in various industries. This specialized equipment offers unique advantages and capabilities that make it a popular choice for a wide range of applications. In this blog post, we explore what an agitated thin film evaporator is, and how it works, delve into its key advantages, discuss its limitations, and provide insights on choosing the right type for specific applications. By the end, you’ll understand why agitated thin film evaporators are a force to be reckoned with in the world of liquid distillation and concentration.

What is an agitated thin film evaporator, and how does it work?

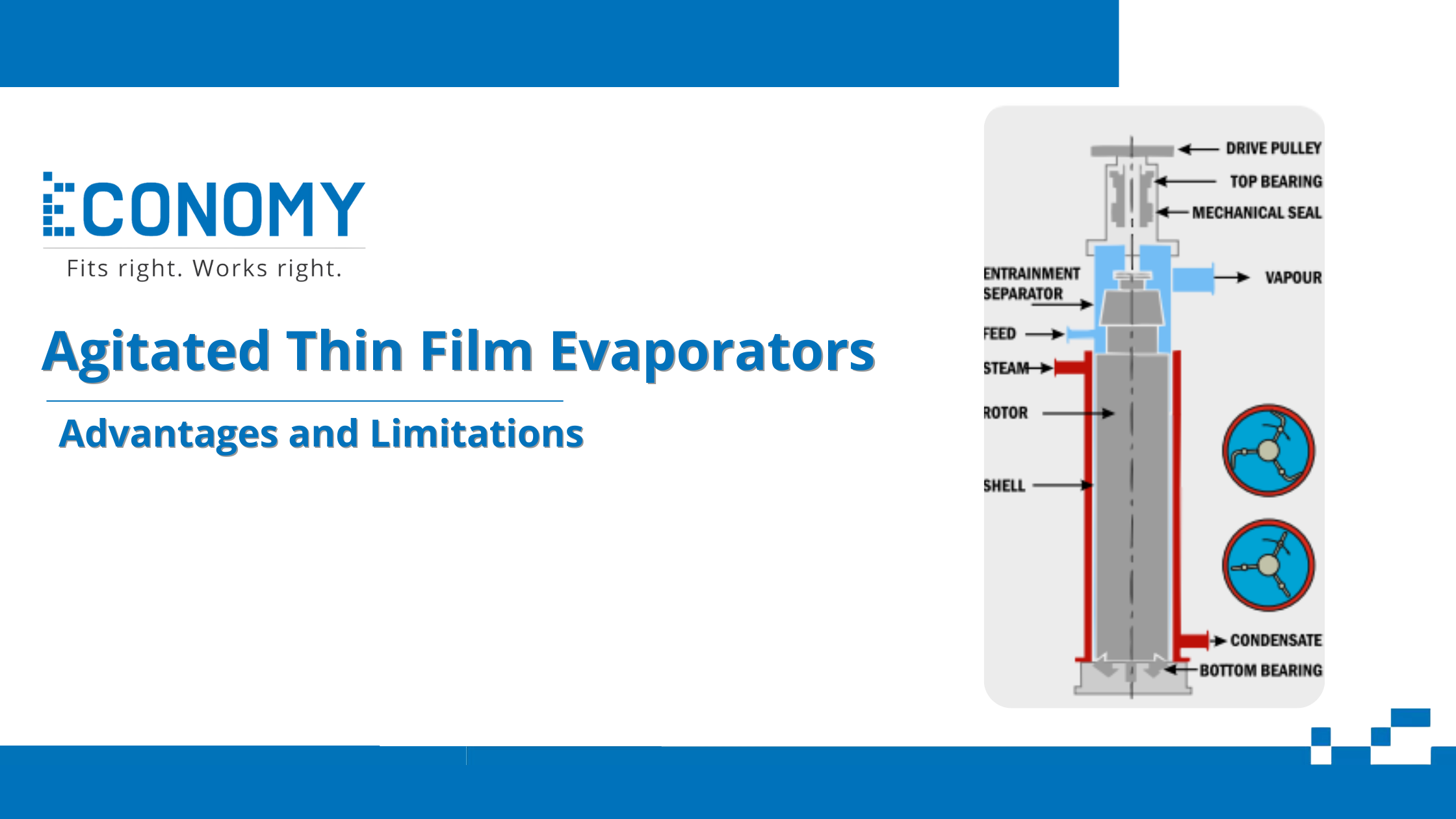

An agitated thin film evaporator is a highly efficient separation device used for the distillation or concentration of liquids. Its design involves a cylindrical evaporator body with a heated jacket and a rotor that creates a thin film of the liquid being processed. As the liquid flows down the heated surface, the rotor agitates it, ensuring even distribution and preventing fouling. The high surface area-to-volume ratio and short residence time in the thin film enable rapid evaporation and efficient separation of volatile components from the liquid.

What are some key advantages of using an agitated thin film evaporator?

Agitated thin film evaporators offer several advantages that make them a preferred choice in many applications. First and foremost, their high heat transfer efficiency results in faster evaporation rates and reduced energy consumption compared to other types of evaporators. The agitated film ensures uniform heat distribution, minimizing the risk of localized overheating and thermal degradation of heat-sensitive materials. Additionally, the short residence time in the evaporator prevents thermal stress on the liquid, making it suitable for processing temperature-sensitive compounds. The continuous feed and discharge capabilities allow for continuous operation, increasing productivity and throughput. Furthermore, the compact design of agitated thin film evaporators saves valuable floor space and facilitates easy integration into existing processing systems.

What are some limitations associated with agitated thin film evaporators?

While agitated thin film evaporators offer numerous advantages, they also have some limitations to consider. One limitation is their relatively higher initial capital cost compared to other types of batch evaporators. Fouling can be a concern, especially when processing materials with high viscosities or that tend to form deposits on the heated surface. Regular cleaning and maintenance are essential to ensure optimal performance. Lastly, the limitations in scalability for very large capacities may require multiple units to meet production demands.

How do you choose the right size of agitated thin film evaporator for a specific application?

Choosing the right size of agitated thin film evaporator depends on various factors specific to the application. Considerations include the desired evaporation rate, liquid properties (viscosity, boiling points, heat sensitivity), required separation efficiency, and the need for continuous operation. Consulting with experienced engineers or manufacturers can help in selecting the most suitable configuration for the desired application.

Why agitated thin film evaporators are powerful for distilling or concentrating liquids?

Agitated thin film evaporators have gained prominence in the world of liquid distillation and concentration due to their unique capabilities. The combination of high heat transfer efficiency, short residence time, and continuous operation makes them highly effective for separating volatile components from liquids. Whether it’s purifying pharmaceuticals, concentrating food extracts, or recovering solvents, agitated thin film evaporators provide a reliable and efficient solution. By leveraging their advantages, industries can achieve precise control over product quality, increase productivity, and reduce energy consumption.

Agitated thin film evaporators offer significant advantages in liquid distillation and concentration processes. Their efficient heat transfer, short residence time, and continuous operation capabilities make them a compelling choice for a wide range of applications. While they may have some limitations, proper selection, operation, and maintenance can overcome these challenges. Agitated thin film evaporators empower industries to achieve high-quality product separations, enhance process efficiency, and meet the demands of diverse liquid processing needs.

At Economy Process Solutions we provide the right fit for all our clients and ensure that we offer a pilot plant facility that enables you to take a trial run of our unit in your processes and experience the benefits in real-time. Reach out to our experts today to avail the same.