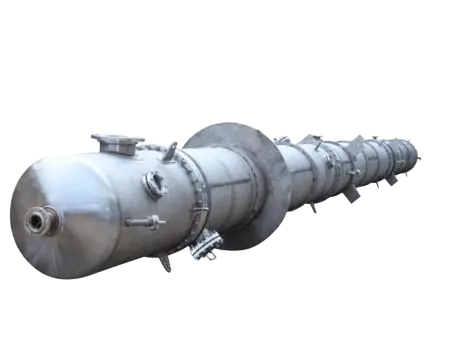

- Economy Solutions offers a range of distillation columns that can be used to separate two boiling components by heat and mass transfer.

- These columns can be batch or continuous and are equipped with suitable packing, a liquid distributor, and other internal components.

- In addition to the distillation column itself, we provide full plant design and automation services to ensure that your distillation unit is highly efficient and integrated with your overall energy system.

- Whether you need a distillation column for a small or large operation, Economy Solutions has a solution that will meet your needs.

- Economy provides a wide range of distillation columns (batch/continuous) with full plant design including automation.

- All distillation units are designed with highly efficient equipment to benefit from energy integration.

- Distillation units are designed with vacuum systems which give desired productivity and quality parameters.

- SPDU (Short path distillation Unit) are designed with various kind of inbuilt vapor separators which help to get desired color of product and reduces carryover.

- These distillation columns are suitable for use in high heat sensitive products, food processing, pharmaceuticals/chemicals, oil and gas industries and oil refining and recycling plants.

- The distillation column is designed to separate two boiling components by heat and mass transfer, using the principle of relative volatility.

- The distillation columns are equipped with suitable packing, a liquid distributor, and other internal components that aid in the separation process.

- The full plant design and automation services provided by Economy Solutions ensure that the distillation unit is highly efficient and integrated with the overall energy system

- Distillation units are designed with vacuum systems which gives desired productivity and quality parameters.

- SPDU (Short path distillation Unit) are designed with various kind of inbuilt vapor separators which helps to get desired color of product and reduces carryover.

Request for Product Specifications

- Product Purification

- Cooler

- Product Seperation