The Complete Guide to Selecting the Right Dryer for Your Process

Just as you can tell by the name, a process dryer or an industrial dryer is an industrial equipment used for drying up objects. But when it comes to actually using and choosing process dryers, things get much more complex.

Since different industrial applications and uses will require different process dryers, it is highly important to know how to choose the right dryer for your process. Since the right dryer can make your manufacturing process much faster, more efficient, and even cheaper, we are here to help. You can go through this guide on how to choose the right dryer for your process and easily pick the right dryer for your needs.

Understanding the Selection Process

Before covering anything else regarding process dryers, let’s understand the selection process. This simply means knowing the factors and details that are important to learning how to choose the right dryer for your process.

Factors to Consider when Choosing a Dryer for a Process

Even though there can be countless factors to consider while getting a process dryer depending on your needs, there are only a few key ones that are important for learning how to choose the right dryer for your process. This primarily includes the following factors regarding process dryers:

-

Material Characteristics: The type of process dryer needed for your process depends on the type of material you want to dry up.

-

Production Volume: You will need a large process dryer for larger production volumes and vice versa.

-

Required Quality: If you want a well-dried end product, then getting a high-performance dryer is definitely a must.

How to Choose the Right Dryer for Your Process?

Based on these key factors, you must have a pretty good idea of how to choose the right dryer for your process. But to be on the safer side, you should consider these points as well for picking the right process dryer:

Step-by-Step Guide on the Selection Process for Choosing a Dryer

-

Process Requirements: Before anything else, you should consider the process requirements. This essentially includes checking the factors explained previously that affect the overall drying process.

-

Available Options: Once considered, you should also check the types of process dryers available in your region.

-

Budget Constraints: Lastly, you need to consider your budget as well since you will need to get something that you can afford.

Process Dryers Information

Now that we have gone through the key factors for choosing the right dryer for your process, choosing the right one should be much easier. However, you should also know process dryers information and the different types of process dryers available in the market to pick the right one.

Different Types of Process Dryers Available in the Market

Out of the various types of process dryers available out there, here are some of the common ones:

-

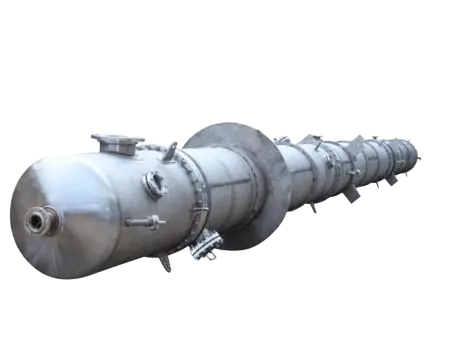

Rotary Dryers: These are highly common dryers where a cylinder rotates around the material while drying it up using hot air.

-

Fluidized Bed Dryers: These involve vaporizing a liquid material and then drying the vapors using hot air to dry them up.

-

Spray Dryers: In such dryers, the material goes from a liquid state to a solid state as it is dried up quickly because it is sprayed into small molecules.

Industries using Process Dryers

Since there are so many types of process dryers available out there, you might be wondering about their typical applications and where they get used. Typically, you will find them being used in common industries like:

-

Food Processing: Most large-scale food industries will need to dry the final product or one of the ingredients using a process dryer.

-

Pharmaceuticals: Many tablets use liquid ingredients that first need to be dried up using a process dryer.

-

Chemicals: A process dryer can be used to stop a chemical reaction or change its state.

-

Textiles: Once clothes are dyed, they quickly need to be dried using the right type of process dryer.

Explore Advanced Features and Drying Options

While process dryers have been used for multiple years now, modern ones offer various new features. So, if you are going with a modern rotary vacuum paddle dryer or an agitated nutsche filter dryer, then you can enjoy advanced features like these:

-

High Efficiency Designs: Thanks to their highly insulated outer shells and overall efficient designs, modern process dryers offer excellent efficiency.

-

Automated Functions: Thanks to its automated functions, modern process dryers can handle all tasks independently.

-

Advanced Control Systems: If your process dryer is connected to a computer, sending advanced control commands becomes much easier.

Conclusion

Whenever you are working with liquids or wet products in manufacturing, it is highly important to dry them off quickly and properly. Since this is quite vital for saving manufacturing time and product finish, you should get the right dryer for this. Therefore, we have already given a detailed guide on how to choose the right dryer for your process up above. You will get to know everything about process dryers, their types, common applications, dryer recommendations, and pretty much everything else about how to choose the right dryer for your process. If this guide has helped you to learn how to choose the right dryer for your process, consider leaving your thoughts in the comments section below.