Single Stage Short Path Distillation in API Recovery - Process Advantages

The short path distillation unit plays a very crucial role in today’s pharmaceutical sector, especially when it comes to the recovery of heat-sensitive APIs. The unit operates at low pressure, which prevents the breakdown of delicate compounds. Its biggest advantage is that it provides high recovery even at low temperatures, which keeps the molecular structure of the APIs safe and maintains their medicinal effectiveness.

When pharma companies require ultra-high purity, they prefer short-path distillation units, as traditional methods such as multi-stage distillation or crystallization can sometimes damage the APIs. Another great feature of this unit is that it is energy-efficient. Today, there is pressure in the industry to increase production but reduce waste and energy consumption. The short path distillation unit maintains this balance perfectly, which leads to maximum utilization of raw materials and improves environmental sustainability along with profitability.

The most interesting thing? This system works at every scale; be it small R&D labs or large pharmaceutical manufacturing plants, the short path distillation unit can be easily integrated into existing setups.

What is API Recovery?

The API recovery process typically refers to the healing procedure.

It involves extracting precious energetic pharmaceutical substances from byproducts or combos that were earlier considered waste. These are called APIs. Ideally, this process not only enhances the performance but also improves sustainability and price-performance ratio.

When APIs are recovered and reused, the demand for raw materials is reduced, and waste disposal costs are saved. Recovery methods include filtration, crystallization and distillation. Still, when the compound is heat-sensitive, a short path distillation unit is the most effective solution as it safely and efficiently recovers delicate materials.

Role of SPD

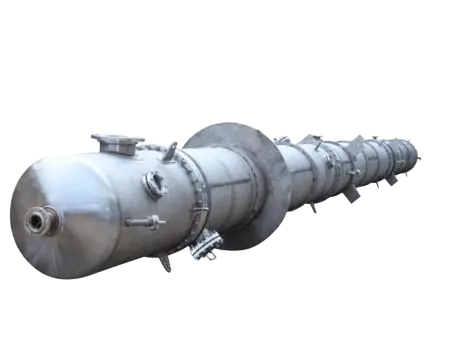

Short path distillation unit is designed to provide efficient separation at low pressure. It has a very short distance between the evaporator and the condenser, which reduces product loss and gives high purity recovery, that too at low temperatures. In the pharma industry, APIs are very sensitive, and it is important to maintain their integrity.

When traditional distillation is too harsh or inefficient, a short-path distillation unit is used. It maintains a vacuum, which reduces boiling point and does not damage sensitive molecules. The system is flexible, meaning it works in both small batches and continuous production. Pharmaceutical companies benefit from its scalability and precision, and it can be easily integrated into existing production setups. Hence, the demand for SPD is consistently increasing in pharma labs and manufacturing.

Benefits of Single-Stage Systems

A single-stage short-path distillation unit has several benefits.

Firstly, the product is processed only once, saving time, energy, and labor. Repeated processing is not required, and the risk of contamination is reduced.

Another benefit is easy cleaning and maintenance. Hygiene is of utmost importance in the pharma industry, and switching between batches or products is quick in a single-stage system. It increases productivity.

Single-stage systems are compact and perfect for space-limited labs. Despite the small size, their separation efficiency is top-class.

And most importantly, single-stage systems provide precise control over temperature, pressure, and feed rate. This means consistent product quality and maximized API recovery.

For pharma companies, this is a powerful combination of profitability, waste reduction, and sustainability. With increasing regulatory pressure, adopting efficient and clean technologies such as single-stage short-path distillation is not just a choice but a necessity.

EPS Capabilities

EPS short-path distillation units are specially designed for pharma. Their material can withstand high vacuum and continuous operation. EPS systems' precision rotors, corrosion-resistant surfaces, and durable seals make them reliable in the long term.

EPS distillation columns can be customized to each client's specific needs. Whether a compact benchtop system or an industrial-scale setup, EPS tailors the solution. Advanced temperature and pressure controls allow you to fine-tune each distillation run to improve purity and recovery rates.

EPS also integrates its vacuum pumps for pharma, which achieve the ultra-low pressure needed for sensitive compound separation. Their modular systems can be easily upgraded, and maintenance is simple.

EPS's decades of expertise and solid after-sales service ensure that every pharmaceutical system operates at peak performance. Whether developing new formulations or scaling up production, EPS's solutions deliver superior API recovery and compliance with strict pharma regulations.

Case Study

A leading pharmaceutical company was unable to recover its high-value APIs using traditional distillation. They approached EPS and had a customized short path distillation unit installed for their process. Within weeks, the company reported a 25% recovery improvement, less thermal degradation, and lower energy use. EPS’s vacuum pumps for pharma kept the system stable, even in demanding conditions. EPS’s partnership improved both its profitability and product quality. This case shows how advanced SPD technology can transform pharma processes.

Looking to optimize your short-path distillation unit? Visit /products/distillation-columns/ and /products/vacuum-pumps/ for complete pharma recovery solutions for EPS!

Conclusion

In today's pharmaceutical world, adopting a short-path distillation unit is not just a way to keep up with the competition, it is a necessary step that improves efficiency, purity and sustainability in every pharmaceutical process.

When pharmaceutical companies work on small batches or increase their production capacity, the short-path distillation unit becomes an invaluable tool for them. This system is so precise and reliable that it improves the API recovery process at every stage - without damaging the compound.

Companies around the world are now demanding clean, fast and cost-effective solutions. In this changing trend, the short path distillation unit is emerging as a game-changer. It not only reduces waste but also helps companies reach their profitability goals by maintaining product quality. At the same time, it also becomes easier to meet strict pharma standards and regulations.

Today, setting up a short-path distillation unit is a smart investment for the pharmaceutical industry leading them to long-term success and sustainability.

FAQ

1. What is a short path distillation unit?

This is a system that separates heat-sensitive compounds at low temperatures.

2. How is SPD used in API recovery?

SPD purifies APIs by applying vacuum and gentle heat while maintaining their integrity.

3. What makes EPS’s SPD unique?

EPS’s system is customized, durable, and pharma-specific, with advanced controls.

4. What are the benefits of traditional distillation?

SPD is faster, cleaner, and energy-efficient, reducing both contamination risk and waste.