Industrial Evaporators vs. Conventional Dryers: Which is Right for You?

Every processing plant eventually faces the same challenge: how do you remove water or solvents in the most efficient way? Most of the time, the choice boils down to two options industrial evaporators or conventional dryers. Both are designed to reduce moisture, but they work in very different ways and serve very different purposes.

Choosing the right one can have a major impact on operating costs, product quality, and long-term reliability. In this article, we’ll walk through how each system works, where they’re used, and what you need to weigh in terms of efficiency, cost, and maintenance.

Basic Principles of Each

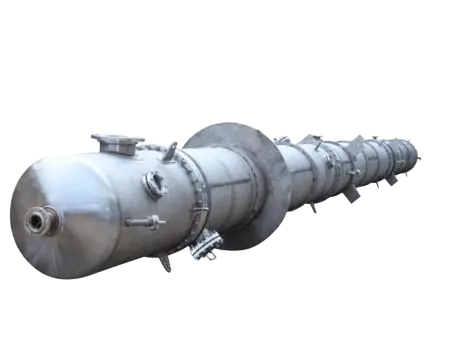

Think of an industrial evaporator as a concentration tool. Its job is to heat up a liquid until part of it flashes off as vapor. That vapor is condensed and collected, while what’s left behind is a thicker, more concentrated liquid.

Plants use evaporators when the liquid itself is valuable like fruit juice, pharmaceutical solutions, or chemical solvents that can be recovered and reused. There are plenty of designs—falling film, forced circulation, multi-effect—but the core idea is always the same: controlled heating and careful vapor separation.

A dryer, by contrast, takes things a step further. Instead of just concentrating, it strips out almost all the moisture to leave you with a solid product.

How it does that depends on the setup. Rotary drum dryers tumble solids in a stream of hot air, spray dryers turn liquid into a fine mist that dries almost instantly, and tray dryers use gentle heat over time. The outcome could be a powder, a granule, or a flake—something that’s stable, easy to store, and ready for packaging or further processing.

Put simply: evaporators give you a concentrated liquid; dryers give you a dry solid.

Key Application Areas

Whether you choose an evaporator or a dryer really depends on the form you want your product to take at the end of the line.

Take food processing, for example. Juice makers and dairy plants lean heavily on evaporators to pull out water before packaging or shipping.

Concentrating liquids this way cuts transport costs and helps preserve freshness. But if you want milk powder or instant coffee, you’ll need a spray dryer. That's the step that turns a liquid concentrate into a fine, shelf-stable powder. In many cases, the evaporator does the prep work, and the dryer finishes the job.

The chemical industry tells a similar story but with different products. Evaporators are used to strengthen brines, acids, or resin solutions, while dryers step in when the goal is a powder or crystalline solid like salts, pigments, or polymers.

In pharmaceuticals, the split is even more distinct: evaporators recover solvents and concentrate intermediates, while dryers produce the final active ingredient in solid form, ready for tableting or blending.

Mining and metallurgy add yet another angle. Here, evaporators are often part of wastewater treatment or zero liquid discharge setups, where the goal is to shrink liquid volumes. The concentrated residues that remain are then passed to dryers, making them easier and safer—to transport or dispose of.

Energy Efficiency Comparison

Energy use is one of the biggest dividing lines between evaporators and dryers.

Evaporators, especially multi-effect designs, are built with efficiency in mind. Heat from one stage is recycled into the next, so the steam you’ve already paid for keeps working harder. Add in technologies like mechanical vapor recompression (MVR), and efficiency climbs even further making evaporators a smart choice whenever you’re stripping out large volumes of water or solvent.

Dryers, on the other hand, tend to be power-hungry. Moisture locked inside solids is harder to remove, so dryers rely on long heating cycles, hot surfaces, or moving large amounts of hot air. That adds up quickly in terms of energy bills. Spray dryers, for instance, are incredibly effective but also notorious for their energy appetite.

In practice, many plants run the two in sequence: use an evaporator first to knock down the bulk water load, then switch to a dryer for the final step. It’s a compromise that saves energy overall without sacrificing product quality.

The bottom line? Evaporators usually win on energy efficiency, while dryers remain essential when the end goal is a fully dry solid.

Cost and Maintenance

When it comes to cost, the two systems sit on opposite ends of the spectrum.

Evaporators usually carry a heavier price tag upfront. Multi-effect or recompression units are complicated machines with heat exchangers, pumps, condensers, and plenty of points that need watching.

They’re also prone to scaling and fouling, especially when the feed contains salts or solids, which means cleaning and descaling are part of the routine. The flip side is that once they’re running efficiently, their lower energy use can chip away at that higher capital cost over time.

Dryers, by contrast, are often cheaper to buy, at least the simpler types like tray or rotary dryers. The catch is in the day-to-day bills.

They chew through a lot of energy, and with moving parts like fans, bearings, ducts, maintenance never really stops. Cleaning is another big one, especially in food or pharma, where contamination risks are high.

For drying large volumes of low-value products, they’re usually the practical answer, but in high-value or sensitive operations, the hidden cost of inefficiency starts to add up.

So, while evaporators need skilled operators and regular cleaning, they often reward plants with long-term savings. Dryers are easier to install and get running, but you’ll likely keep paying for that simplicity in higher operating costs year after year.

Conclusion

At first glance, evaporators and dryers might look like two versions of the same thing but they serve very different purposes. Evaporators are built for concentrating liquids and recovering solvents, usually with much better energy efficiency. Dryers, on the other hand, step in when you need a solid end product, even if that means higher energy use.

In many plants, the smartest setup isn’t choosing one or the other, it’s combining them. Use an evaporator to strip out most of the water cheaply, then finish the job with a dryer. That way, you get the efficiency of evaporation without giving up the flexibility of drying.

In the end, the right choice depends on what you’re making, how much energy you can afford to spend, and the budget you have to work with. Knowing where each technology shines helps you avoid costly mismatches and design a system that actually fits your process.

FAQs

1. What’s the basic difference?

Evaporators are designed to concentrate a liquid boiling off water or solvent and leaving you with a thicker solution. Dryers go further, removing nearly all the moisture so the end product is a dry powder, granule, or solid.

2. Which one saves more energy?

Evaporators generally win here, especially if they use multiple-effect or mechanical vapor recompression designs that recycle heat. Dryers, by comparison, usually draw more power because they’re working on solids where water is harder to remove.

3. Who uses them?

Food companies use evaporators for things like juice concentration, while spray dryers make instant coffee or milk powder. In chemicals and pharma, evaporators recover solvents or strengthen brines, while dryers prepare powders or active ingredients. Mining and metallurgy lean on both evaporators for wastewater reduction, dryers for residues.

4. Can you combine them?

Absolutely. A common setup is evaporator first, dryer second. The evaporator handles bulk water removal at lower cost, and the dryer finishes the job. That combo saves energy while still delivering a dry final product.

5. What about upkeep?

Evaporators need careful operation and routine cleaning to prevent scaling or fouling. Dryers tend to demand more hands-on maintenance like fans, bearings, ducts, and frequent cleaning, especially in food and pharma, where contamination is a risk.