Energy-Saving Strategies for Heat Exchangers in Chemical Plants

In chemical plants, thermal processes sit at the heart of production efficiency, and heat exchangers are the unsung heroes behind them. These systems transfer heat between process streams, often recovering energy from hot effluents to preheat incoming feeds.

Despite their critical role, many facilities still lose valuable energy due to aging equipment, fouling, and inefficient operation. As energy costs climb and sustainability goals become more pressing, optimizing heat exchanger performance is no longer optional, it’s essential.

This article examines the most common challenges in heat exchanger operation, explores new-generation designs and materials, and outlines practical strategies to boost efficiency and reduce energy consumption across chemical plant operations.

Common Challenges in Chemical Plants

Chemical plants depend on continuous heating and cooling cycles to maintain stable, efficient operations. Yet over time, several factors can erode the performance of heat exchangers and drive up energy costs.

1. Fouling and Scaling

Fouling, the buildup of unwanted deposits on heat-transfer surfaces remains one of the leading causes of efficiency loss. Layers of organic residues, corrosion products, or mineral scales act as insulation, lowering heat-transfer coefficients and increasing pressure drop.

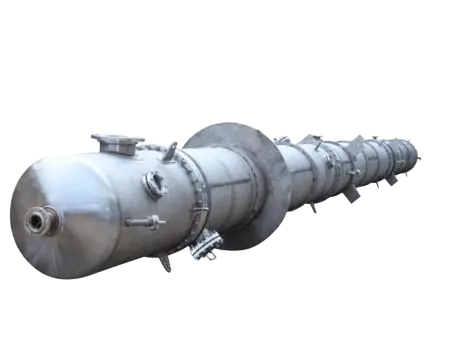

2. Suboptimal Design or Oversizing

Many older facilities still rely on traditional shell-and-tube exchangers designed with wide safety margins. While conservative, these oversized units often result in low flow velocity, weak turbulence, and poor heat-transfer performance.

3. Ineffective Cleaning and Maintenance

When cleaning schedules are delayed or irregular, fouling worsens and energy use climbs. Regular inspection, chemical cleaning, or mechanical pigging can restore efficiency but these tasks are frequently postponed to avoid interrupting production.

4. Energy Loss Through Unrecovered Heat

A significant portion of process heat from condensers, reactors, or drains is often wasted and released to cooling towers or the atmosphere. By integrating heat-recovery exchangers or networked heat-exchange systems, plants can capture and reuse this energy for preheating or other thermal needs.

5. Aging Equipment and Corrosion

As equipment ages, corrosion and erosion gradually reduce thermal conductivity and increase the risk of leaks or mechanical failure. These issues not only lower efficiency but can also lead to costly downtime or product contamination.

Advanced Heat Exchanger Designs

Modern heat exchangers are built to overcome the limits of traditional systems delivering stronger energy performance, better fouling resistance, and higher operational reliability.

1. Plate Heat Exchangers (PHEs)

Unlike large shell-and-tube units, plate exchangers use corrugated metal plates that generate high turbulence and maximize surface area for heat transfer. They’re compact, efficient, and can be opened easily for cleaning — a major plus when dealing with viscous or fouling fluids.

Energy gain: 25–40% higher efficiency than conventional designs.

Typical uses: Reboilers, condensers, and cooling duties in chemical and food plants.

2. Spiral and Helical Heat Exchangers

These units channel fluids in a continuous spiral path, creating a self-cleaning effect that reduces fouling and handles slurry or particulate-heavy streams with ease.

Energy gain: Excellent performance with high-viscosity or fouling-prone applications.

Typical uses: Effluent cooling, reactor heating, and waste-heat recovery systems.

3. Compact or Printed Circuit Heat Exchangers (PCHEs)

PCHEs feature precision-etched microchannels diffusion-bonded into metal blocks. Their dense structure allows extremely high heat flux, supporting faster and more efficient heat exchange in a small footprint.

Energy gain: Compact size with exceptional temperature and pressure resilience.

Typical uses: Hydrogen processing, gas treatment, and specialty chemical operations.

4. Heat Integration via Pinch Technology

Pinch analysis helps engineers identify where heat recovery makes the most sense across the process. By matching hot and cold streams strategically, plants can cut heating and cooling needs by as much as 30%.

5. Hybrid and Regenerative Systems

Hybrid exchangers blend materials like stainless steel and graphite for superior corrosion resistance, while regenerative systems capture and release heat cyclically — ideal for flue-gas recovery or other high-temperature duties.

Tips to Maximize Efficiency

Sustainable energy savings don’t depend solely on new equipment; they also come from smart operation and disciplined maintenance.

1. Regular Cleaning and Fouling Monitoring

Set up condition-based cleaning schedules supported by online monitoring tools such as thermal-efficiency tracking or pressure-drop analysis. These help detect fouling before it becomes a major energy drain.

Whenever possible, use automated cleaning systems like Clean-in-Place (CIP) to save downtime and labor.

2. Optimize Flow Configuration

Design and operate exchangers for counter-current flow to maximize temperature recovery.

Keep flow conditions turbulent typically above a Reynolds number of 10,000 to minimize fouling and maintain high heat-transfer rates.

3. Utilize Waste Heat Recovery

Recover energy that would otherwise be lost. Adding secondary exchangers to boiler blowdown lines, compressor discharges, or distillation columns can capture valuable waste heat.

Reuse that recovered heat for preheating feedwater, raw materials, or even HVAC systems.

4. Upgrade to High-Performance Materials

In corrosive or high-temperature services, materials like titanium, graphite, or high-grade alloys can improve durability and heat-transfer performance.

Surface coatings such as fluoropolymers also help extend exchanger life and reduce fouling tendencies.

5. Digital Monitoring and AI Optimization

AI-driven control systems now track exchanger data in real time, identifying fouling early and recommending the best cleaning intervals. Integrating automation with analytics can unlock an extra 5–15% in annual energy savings through optimized energy recovery and reduced downtime.

6. Heat Exchanger Network Optimization (HEN)

Periodic audits of the entire heat-exchanger network can reveal hidden inefficiencies. Rearranging streams or retrofitting older units often delivers significant energy gains without major capital expense.

Conclusion

Energy efficiency in chemical plants starts with smarter heat exchange. By combining modern designs, optimized flow control, and data-driven maintenance, facilities can cut energy use and costs while advancing their sustainability targets.

Whether it’s through compact exchangers, waste-heat recovery systems, or AI-enabled performance monitoring, the potential savings are substantial — often recouping investment in just one to two years.

Upgrading the heat exchanger strategy isn’t just an engineering improvement; it’s a decisive move toward greener, more resilient, and more competitive chemical operations.

Frequently Asked Questions (FAQs)

1. How do heat exchangers help save energy in chemical plants?

Heat exchangers capture energy from hot process streams and use it to preheat cooler fluids. This recycling of heat cuts down the need for external sources like steam or electricity, directly reducing energy costs.

2. Which heat exchanger designs offer the best efficiency?

Plate, spiral, and printed circuit exchangers lead the pack. Their high surface area, compact design, and strong resistance to fouling make them ideal for maximizing heat transfer and minimizing energy loss.

3. What industries benefit most from advanced heat exchangers?

These systems are widely used in chemical and petrochemical plants, as well as food and beverage, power generation, and pharmaceutical facilities, wherever heat recovery, energy savings, and process control are top priorities.

4. Are there measurable cost savings?

Absolutely. Enhanced heat-transfer efficiency can reduce overall energy expenses by 10–30%, with many facilities seeing a return on investment within the first year through lower steam use and less downtime.

5. How often should heat exchangers be serviced?

Maintenance frequency depends on the process and fouling tendency, but a 6–12 month interval is typical. Plants that employ AI-based monitoring or online fouling detection can safely extend cleaning cycles while maintaining performance.