Agitated Thin Film Evaporators in the Chemical Industry: Innovations and Sustainability

Those of you who are familiar with industrial equipment must know that using a high-performance and the right type of evaporator is essential for optimum results. While there are various types of evaporators out there, agitated thin-film evaporators in the chemical industry have seen a lot of growth in the past years.

Therefore, we are here with a complete guide on agitated thin-film evaporators, their applications, future trends, and pretty much everything else that you need to know to understand their situation in the chemical industry.

What is an Agitated Thin Film Evaporator (ATFE)?

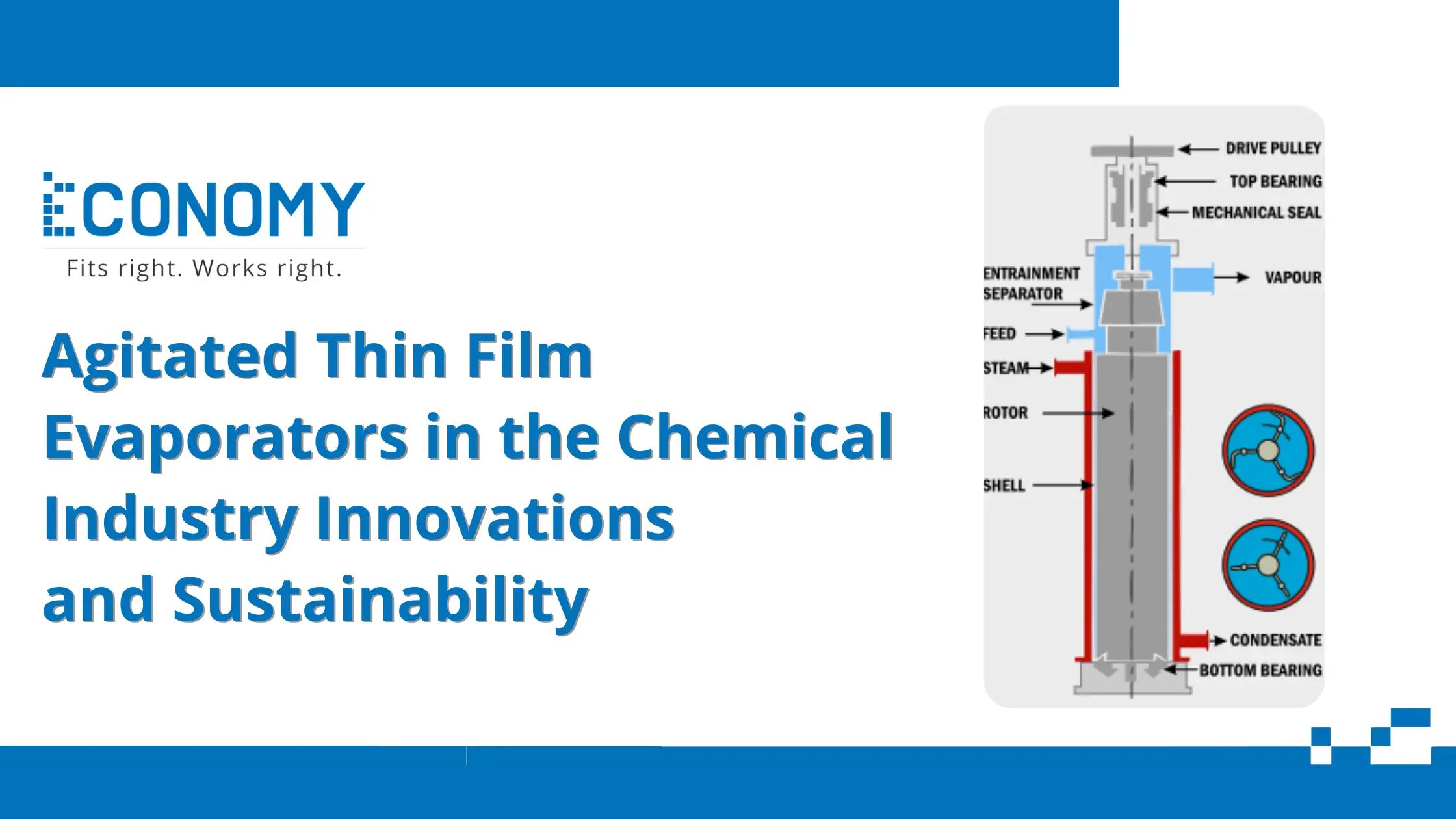

Before anything else, you should first understand what exactly an agitated thin film evaporator or ATFE is. Just per the name, an agitated thin film evaporator uses a blade to agitate or spread out a liquid on a heating surface forming a thin film. This heating surface then turns this liquid into vapor where the efficiency is increased because of the thin film formation. And because the blade keeps rotated, a new layer keeps forming again and again leading to the separation of the liquid and vapor.

How ATFEs Operate and Their Efficiency in Chemical Processes?

Now that you know the basics, let’s take a look at the operation and efficiency of agitated thin film evaporators in the chemical industry. Starting with the operation, we have already covered the working principle up above. The operation primarily depends on the rotary blade that keeps creating a thin film again and again. Similarly, because you are only heating up a thin liquid film, you get an increased efficiency which is quite great to have.

Innovations in Agitated Thin Film Evaporators

While the key working principle of all agitated thin film evaporators in the chemical industry has remained the same over the years, newer ATFEs are coming up with all kinds of innovations. Since these innovations are making ATFEs even better, you should definitely know some of the major ones:

-

Design: Starting with the design, modern ATFEs have improved designs that offer better performance over time.

-

Materials: By using better materials with increased heat transfer, newer ATFEs available in the market can further improve performance.

-

Energy Efficiency: Most importantly, newer ATFEs can expect much higher efficiency thanks to better designs that increase performance and make the ATFE more efficient.

Sustainability in Agitated Thin Film Evaporators

Whenever you are working with any kind of chemicals or chemical processes, it is highly important that you are going for sustainable practices. If you want to continue using a chemical process, optimizing sustainability is quite important which is also true for ATFEs:

-

Reduced Energy Consumption: Since ATFEs are highly efficient and offer high performance output, you can achieve reduced energy consumption as well.

-

Waste Minimization: Because ATFEs don’t require high amounts of solvents, using agitated thin film evaporators in the chemical industry also minimizes waste production.

-

Environmental Impact: When you combine these and other benefits of ATFEs, you can definitely make a good environmental impact over a long period of time when you are talking about industrial scales.

Applications of Agitated Thin Film Evaporators in the Chemical Industry

Talking about the applications and uses of agitated thin film evaporators in the chemical industry, they can be useful in various ways. And some of the common applications of agitated thin film evaporators in the chemical industry include:

-

Solvent Recovery: ATFEs are used to recover substances like glycerin from residues.

-

Concentration of Chemicals: When working with chemicals and drugs, ATFEs can be used for the concentration of the same.

-

Purification Processes: ATFEs can also be used to purify fine chemicals, polymers, and rubber products.

Future Trends and Outlook

While ATFEs already have widespread applications in the chemical industry, they are only going to get better with time. And thus, despite the already existing growth of ATFEs in the last few years, you can expect to see even further growth in the use of ATFEs in the chemical industry. This is primarily made possible thanks to the excellent sustainability and efficiency you get with ATFEs. Both of these factors are going to be highly crucial going forward in industrial technologies and improvements.

Conclusion: Agitated Thin Film Evaporators in the Chemical Industry

Now that we have covered every detail regarding agitated thin film evaporators in the chemical industry, you must understand why these are perfect for so many applications. Most importantly, because of newer innovations, these are going to get even more popular in the future. Lastly, because they are highly sustainable, these are much better all-around evaporators.