At Economy Process Solutions, we take pride in offering complete skid-mounted systems that streamline installation and enhance overall system efficiency. Our solutions are designed for fully automatic operation, powered by a PLC-based SCADA (Supervisory Control and Data Acquisition) system. This allows for optimized operational control and monitoring, ensuring seamless performance. By integrating these advanced technologies, we not only deliver cost-effective solutions but also adhere to stringent environmental regulations. This reflects our commitment to sustainability and responsible industrial practices, as we strive to create a better future for our planet.

- Use of MEE and ATFD reduces operating and disposal cost.

- Use of forced circulation evaporator minimize scaling in evaporator.

- Indirectly heated dryer gives no dusting,smell or air pollution as in case of direct contact dryer like spray or flash dryer.

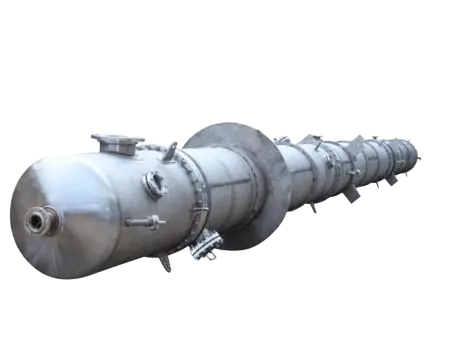

- Complete skid mounted system can be offered.

- Fully automatic operation is achieved by PLC based SCADA system

Request for Product Specifications